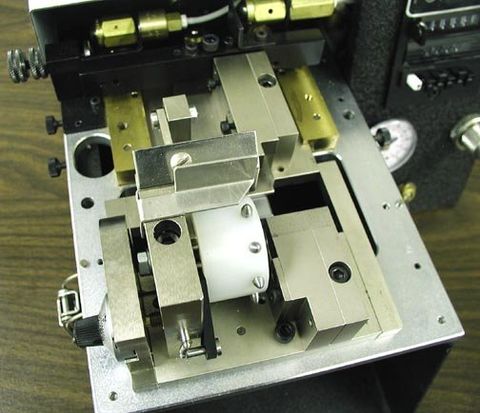

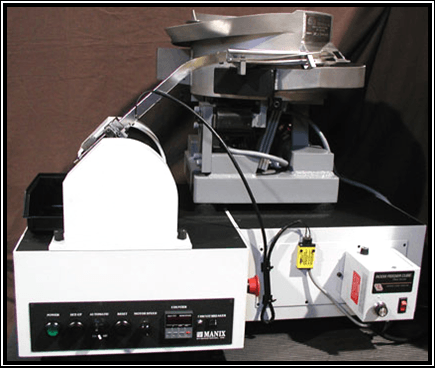

CF Tape Fed Radial Lead Former

Cut and form, form only, and/or cut only all styles of radial components with the Manix range of automatic radial lead forming systems. Whether your components are on tape or loose, Manix has a machine to fit your production rate and your budget. Choose from the tape fed CF Radial, or the workhorse tube or loose fed K-25, or even the economical and world best seller Variocut.

CF Tape Fed Radial Lead Former

OVERVIEW

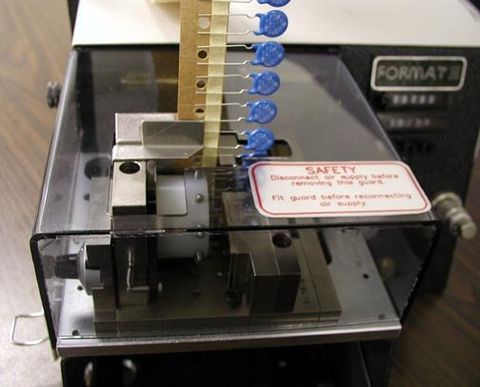

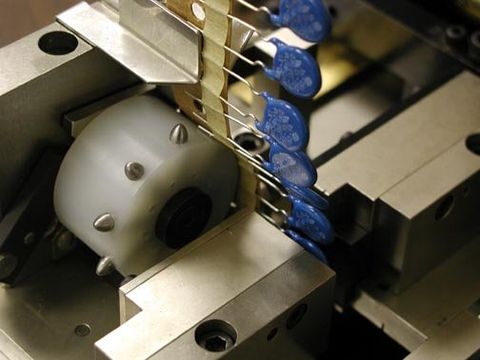

Taped radial components can be cut-only, 90 degree layover, snap-in, stand-off, SMT Reflow form, and even flush mount lock-in forms. Easily swap from transistors to capacitor to LEDs by removing the quick the change inserts. Fully pneumatic, this robust system assures reliable performance over a long operating life.

PRODUCT FEATURES

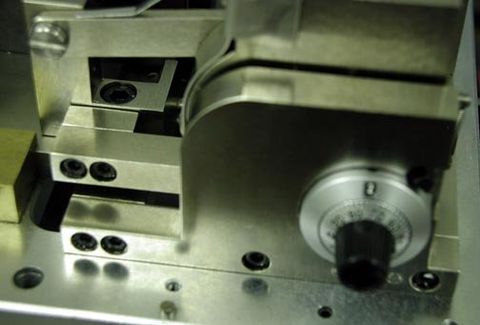

Cut length and stand-off height are dial adjustable.

System includes a reel holder, tape feeder, cut and form tooling and a machine base which can be purchased with an optional machine stroke counter.

Process radials at speeds up to 20,000pph.

Tooling inserts are manufactured of hardened tool steel to ensure repeatable performance.

SPECIFICATIONS

Activation: Automatic or foot pedal, Pneumatic.

Rate of Forming: Up to 20,000 parts per hour.

Size: 12”W x 20”D x 8”H

305mm x 508mm x 203mm

Weight: 45 lbs., 20.5 Kgs.

Air Required: 80 psi.

Types of Components: Transistors, Capacitors, LEDs, Hall Sensors

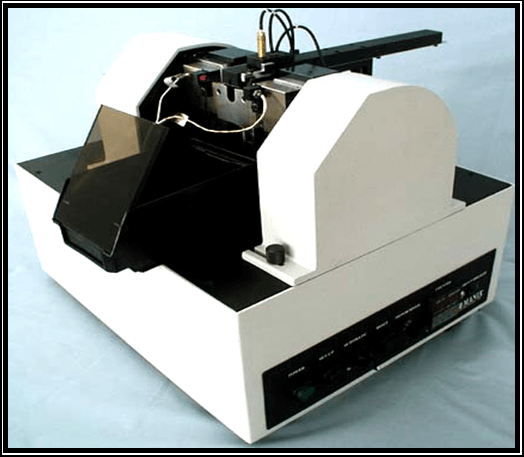

K-25 Radial Lead Forming System

OVERVIEW

Custom form the leads of transistors, capacitors, LEDs and other radial components into new and unusual shapes. Regardless of whether your components are packaged in bulk, tubes or magazines, Manix can custom configure the K-25 to meet even the most demanding requirements. Re-form leads for new hole patterns, create lock-ins and stand-offs, and even prepare leaded components for surface mounting with the quick change cut and form tooling. A complete system consists of a rugged motorized base, a feeding system interface, and individual die sets.

PRODUCT FEATURES

Cut and form radial components to Mil-Spec quality.

Snap-in, Stand-off, Lay-over, and Cut-only tools available.

PLC controlled ensures easy operator interface.

Choose from vibratory bowls, adjustable tube holders, and hand feed chutes.

Component leads clamped before cutting and forming.

Process loose components as fast as 3,600pph.

SPECIFICATIONS

Rate of Forming: Up to 3,600 parts per hour.

Dimensions: 17”W x 28”D x 16”H

432mm x 711mm x 406mm

Weight: 80 - 150 lbs. (depends on feeder)

37 – 69 Kgs.

Air Required: 80 psi.

Power Requirements: 110/220V 50/60 HZ

Types of Components: Loose or tube transistors, LEDs, SIPs. ZIPs

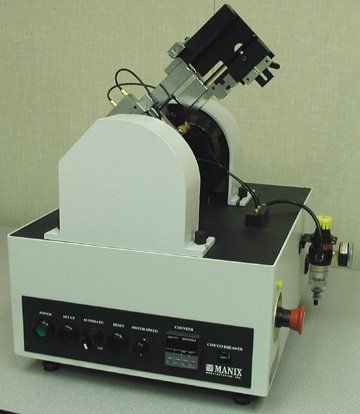

Taped Radials Lead Cutter

OVERVIEW

Cut taped radial components at speeds up to 20,000pph with the famous Variocut lead cutter. The field proven Variocut cuts taped radials to your desired length. Transistors, capacitors, electrolytics, hall sensors, and LEDs can all be processed on this hand-crank system. Cut length adjustment is made by simply turning one screw. This machine has a reputation for reliable, economical performance in thousands of PCB assembly factories worldwide. Simply turn the handle and parts are cut to length and deposited into a collection bin.

PRODUCT FEATURES

Cut only taped radial components.

Choose from two models, one for 0.500”/12.7mm tape hole centers, or one for 0.591”/15mm tape hole centers.

Cut taped component leads up to 0.032”/0.8mm.

Options include a reel holder, and component counter.

Variocut mounts on any tabletop with the included C Clamp.

SPECIFICATIONS

Activation: Hand crank.

Rate of Forming: Up to 20,000 parts per hour.

Types of Components: All Taped Radials.

Systems Available: 0.500”/12.7mm or 0.591”/15mm tape hole centers.

Dimensions: 6.9”/175mm L x 5.7”/145mm W x 6.3”/160mm L

Weight: 4.18 lbs. / 1.9 kgs.