Custom Lead Formers

Manix Manufacturing, Inc. is a leading supplier of custom lead formers worldwide. All systems are designed and manufactured in our U.S.A. manufacturing facility. High volume, low volume, axial, radial, or flat pack, Manix can custom design a system to meet and exceed your specifications. Components that are loose, tubed or taped can be cut and formed to your dimensions.

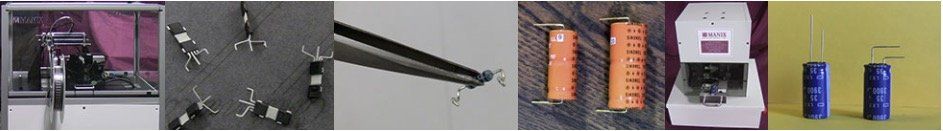

Stand-alone systems with PLC control can be designed to cut and form your most troublesome components. Magnetic hall sensors fed from plastic tape carriers can be picked from the tape, deposited into the cut and form tooling and then presented for operator or robotic pickup. Options can include bar code reading, smart cut and form tooling, custom software design, and table top or stand-alone. All systems are designed and produced in Feasterville, Pennsylvania.

Loose axial electrolytics are cut and formed to specification while maintaining proper polarity orientation. A sensor detects the polarized side and confirms that the cutting and forming operation can be begin. Once loaded correctly, the machine will go green. The operator simultaneously depresses the two green lit switches, and the operation begins. A shuttle table holding the component retracts and positions itself under the cut and form tooling. Once in place, the cut and form tooling actuates and produces a finished component. The component is then presented for pickup.

Systems can be designed for virtually any component and to any shape. Contact a Manix Sales Representative to discuss your lead forming applications.