SINGLE STROKE LEAD FORMING

Cut and form, form only, and/or cut only all styles of axial, radial, and DIP components with the Manix single stroke lead formers. Choose a standard die or have one fabricated to meet your exact lead forming needs. Stand-off, snap-in, or layover are just a sampling of the forms that can be achieved with the line of Manix single stroke lead formers. Operating on 80 psi, these easy to install machines set-up in less than five minutes. Die changeover is typically loosening and removing two socket head cap screws.

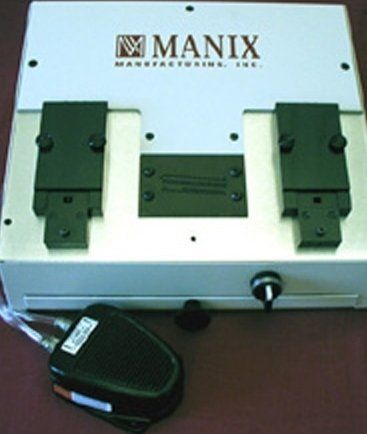

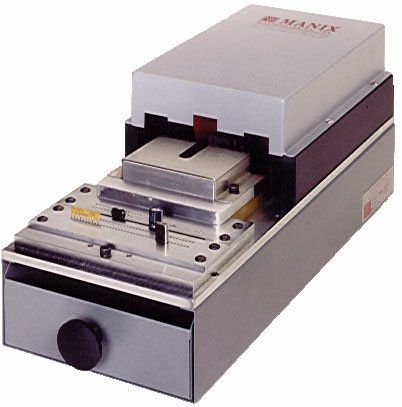

SS-2000 Three-In-One Work Center

OVERVIEW

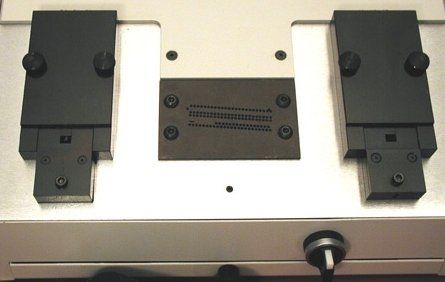

Cut and form all types of loose components with the unique three position SS-2000 single stroke lead former. Each system includes two cut and form dies of your choice, plus a universal trim plate which cuts only a variety of loose components, such as capacitors, LED’s, or IC’s. Simply select the position to be used, insert the component, depress the foot pedal, and remove the finished component.

PRODUCT FEATURES

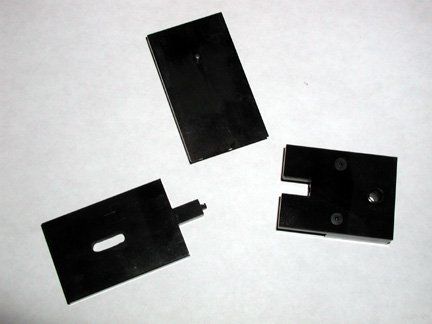

Choose from a broad assortment of cutting and forming dies.

Two positions for cutting and forming.

One position with universal plate for cut only.

Customize a forming die or cut plate to your specification.

Fully pneumatic machine install in minutes.

SPECIFICATIONS

Activation: Foot pedal, Pneumatic.

Rate of Forming: Up to 1,000 parts per hour.

Dimensions: 14”W X 12”D X 7.5”H.

356mm X 305mm X 191mm.

Weight: 55 lbs., 25 kgs.

Air Required: 80 psi.

Paint: Powder Coat, off white.

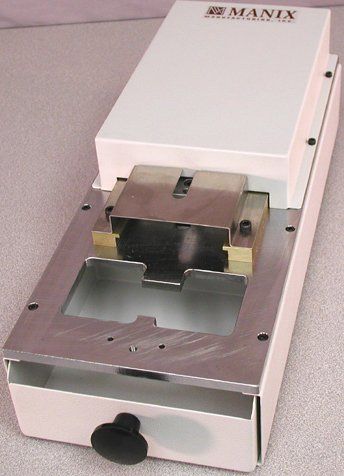

SS-1A Single Position Lead Former

OVERVIEW

The powerful SS-1A base unit accepts standard or custom dies of your choice for cutting and forming and or cutting only axial, radial, and/or IC components. Dies attach in minutes, some as simply as loosening and removing two socket head cap screws. Operating on 80 psi, the powerful base system delivers repeatability, actuation after actuation.

PRODUCT FEATURES

Accepts dies for axials, radials, IC’s, etc.

Simple and reliable low maintenance design.

Precision ground, hardened steel base plate ensures long life.

Changeover in less than two minutes.

Foot pedal actuation frees hands for quick loading

SPECIFICATIONS

Activation: Foot pedal, Pneumatic.

Rate of Forming: Up to 1,000 parts per hour.

Dimensions: 15”L X 6”w X 5”H.

381mm X 152mm X 127mm.

Weight: 17 lbs., 7.7 kgs.

Air Required: 80 psi.

Paint: Powder Coat, Off White.

SS-Trim System

OVERVIEW

When heavy duty cutting is required, the SS-TRIM System is the machine to choose. Available with various cylinders strokes and bores, determined by the cutting application. The system is comprised of a base machine, a trim plate to your specifications, a cutter blade and tooling to marry the trim plate and cutter to the base machine. Operating on 80 psi, the powerful trim system delivers repeatability of cut, actuation after actuation.

PRODUCT FEATURES

Cut Capacitors, IC’s, LED’s, Transistors and other radial leads to your desired cut length.

Variety of cylinders available, application dependent.

Precision ground, plated top base plate ensures long life.

Trim plate change in less than 2 minutes.

Foot pedal actuation increases throughput.

SPECIFICATIONS

Activation: Foot pedal, Pneumatic.

Rate of Cutting: Up to 1,000 parts per hour.

Stroke: Cylinder dependent.

Dimensions: 15”L X 6”W X 5”H.

381mm X 152mm X 127mm.

Weight: 20 lbs.

7.1 kgs.

Air Required: 80 psi.

Paint: Powder Coat, Off White.

SS-1HD HEAVY DUTY TRIM SYSTEM

OVERVIEW

Easily cut to length large connectors or other over-sized components with the powerful SS-1HD Trim System. Utilizing a heavy duty 2” stroke cylinder, the system can easily trim to length virtually any component lead, large or small. Simply insert the component into the trim plate. Each trim plate is fabricated in house to your exact specifications. Once inserted, depress the foot pedal. The cutter will move forward, trimming the component leads to the correct predetermined length. The excess waste will be deposited into a waste bin.

PRODUCT FEATURES

Cut connectors and other large components to your desired cut length.

1.875”(48mm) x 6.5”(165mm) cut area.

In house fabrication of trim plates to your exact specification.

Rugged base and powerful pneumatic cylinder en-sure long life.

Hardened tool steel cutter last for many cuts.

Foot pedal actuation increases throughput.

SPECIFICATIONS

Activation: Foot pedal, Pneumatic.

Rate of Cutting: Up to 1,000 parts per hour.

Cut Area: 1.875”L x 6.5”W

48mm x 165mm

Stroke: 2”/51mm

Dimensions: 15”L X 8”W X 6”H.

381mm X 203mm X 152mm.

Weight: 30 lbs./13.6 kgs.

Air Required: 80 psi.

Paint: Powder Coat, Off White

Options: Trim Plates

Safety Interlocks for plate presence.

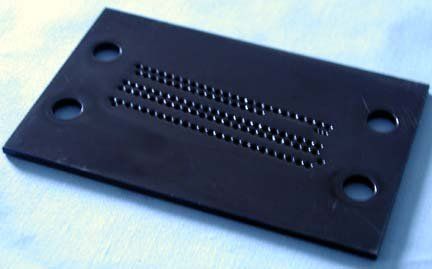

RLC-12 Trim System

OVERVIEW

Trim all varieties of radial leads with the economical RLC-12 lead cutter. Designed for leads under 0.034” in diameter, this low cost trimmer eliminates costly manual trimming after component insertion. The system includes a base machine with a cutter blade, pneumatic cylinder and a foot pedal. Trim plates are optional and can be manufactured to your specification or the off the shelf

RS-U universal plate accepts a variety of components.

PRODUCT FEATURES

Cut Capacitors, IC’s, LED’s, Transistors and other radial leads to your desired cut length.

Choose from a custom trim plate or the universal plate.

Trim plate change in less than 2 minutes

Foot pedal actuation increases throughput.

Sturdy cast aluminum base ensures years of operation.

RSU universal plate handles most radial components.

SPECIFICATIONS

Activation: Foot pedal, Pneumatic.

Rate of Cutting: Up to 1,000 parts per hour.

Stroke: 1” / 25.4mm

Dimensions: 15”L X 5”W X 4”H.

381mm X 127mm X 102mm.

Weight: 7 lbs., 3.1 kgs.

Air Required: 80 psi.

Paint: Powder Coat, Off White.

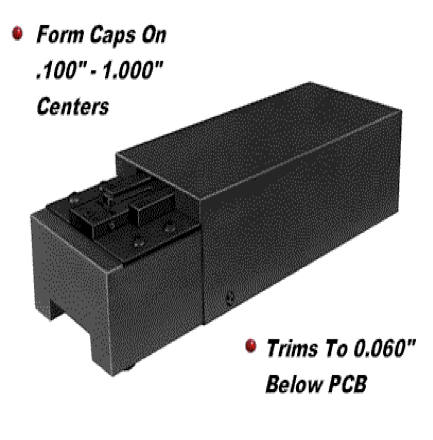

VC Cut and Form System

OVERVIEW

The low cost VC Series from Manix Manufacturing, Inc., reduces circuit assembly cost by eliminating part loss and labor intensive pre or post lead trimming. Choose either the VC-1 for snap-in parts retention or the VC-2 stand-off system for those parts that must be lifted away from the PCB. The system will cut and form capacitors with lead centers from 0.100” to 1.00”.

PRODUCT FEATURES

VC-1 cuts assembly cost by preventing parts fallout during transport of PCB or part lift out during the soldering process.

VC-2 eliminates the need for costly and troublesome spacers providing a uniform height off of the PCB

Both systems are reliable and provide trouble-free service for years to come.

Foot pedal actuation allows hands free actuation and increase throughput.

SPECIFICATIONS

Activation: Foot pedal, Pneumatic.

Rate of Cutting: Up to 1,000 parts per hour.

Stroke: 1” / 25.4mm

Dimensions: 15”L X 5”W X 4”H.

381mm X 127mm X 102mm.

Weight: 8 lbs., 3.7 kgs.

Air Required: 80 psi.

Paint: Powder Coat, Off White.

Capacitors: All types

0.100”-1.00” centers.

2.54 mm- 25.4mm centers.

Protrusion: 0.060” below the PCB.

1.52mm below the PCB.

Custom dimensions available upon request.

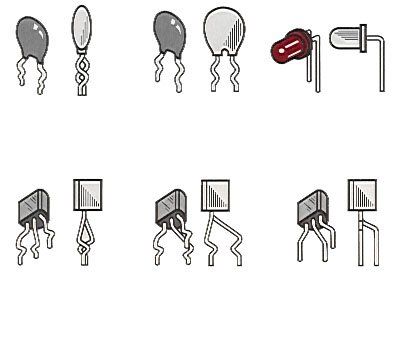

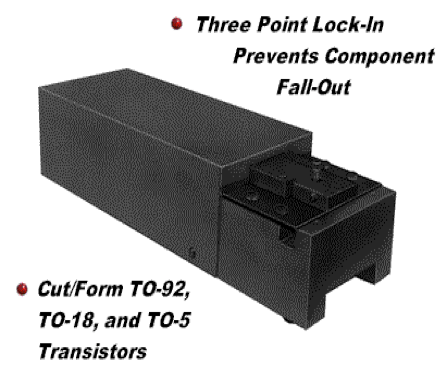

TK Cut and Form System

OVERVIEW

The inexpensive TK Series Lead Formers reduce PCB assembly cost by providing cut and form configurations on the three commonly specified transistor packages. The TK is designed to process leads on all transistors at speeds of up to 1000 parts per hour. The system can be configured to provide snap-in, stand-off or even layover on standard and power transistors. This inexpensive lead former, reduces assembly cost by creating cost saving lead configurations on all transistors. The system is comprised of a compact press, an integrated forming/cutting die, and a foot pedal for hands free actuation.

PRODUCT FEATURES

TK cuts assembly cost by preventing parts fallout during transport of PCB or part lift out during the soldering process.

TK eliminates the need for costly and troublesome spacers providing a uniform height off of the PCB

TK can layover the component so that the body lays flat to the PCB and the leads are bent 90 degrees.

TK systems are reliable and provide trouble-free service for years to come.

Foot pedal actuation allows hands free actuation and increase throughput.

SPECIFICATIONS

Activation: Foot pedal, Pneumatic.

Rate of Cutting: Up to 1,000 parts per hour.

Stroke: 1” / 25.4mm

Dimensions: 15”L X 5”W X 4”H.

381mm X 127mm X 102mm.

Weight: 8 lbs., 3.7 kgs.

Air Required: 80 psi.

Paint: Powder Coat, Off White.

Transistors: TO-220, TO-92, T0-18, TO-5

Protrusion: 0.060” below the PCB.

1.52mm below the PCB.

Custom dimensions available upon request.