FLIP-OVER PCB ASSEMBLY SYSTEMS

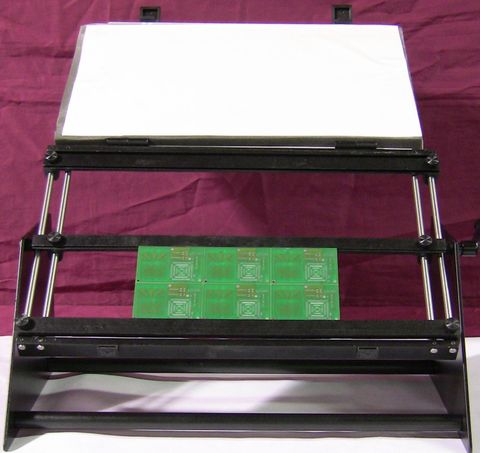

The rugged, self-contained 360/380 flip-over assembly fixtures offer “start-to-finish” PCB assembly (insertion through manual soldering). Choose from two different frame sizes and three different pads. Each feature a heavy duty, tilt-proof base, adjustable 2-rail PCB frame and a dual snap-lock foam padded cover. PCB’s as large as

19” x 9” can fit on the popular 360 while the 380° can accommodate PCB’s as large as 24” x 16”. Full 360° rotation positions the PCB exactly how the operator prefers.

FLIP-OVER PCB ASSEMBLY SYSTEMS

OVERVIEW

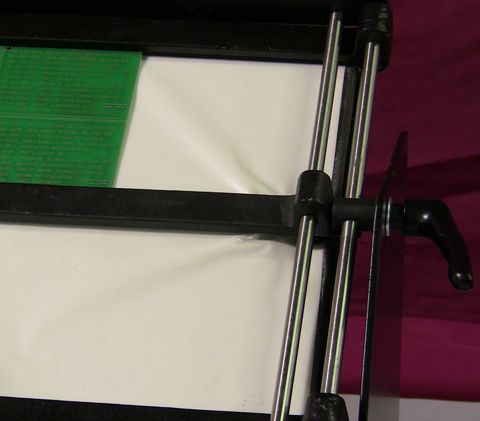

Manix 360 and 380 flip-over fixtures are designed to accept PCB’s of varying sizes. The moveable PCB holding rails adjust easily and offer the capacity to assemble both multiple and single large boards. Components are inserted, immobilized, and rotated for clinching, cutting, and/or soldering. The holding frame rotates 360° and can be locked in any degree. The foam pad prevents components from lifting, or falling out of the PCB during lead trimming or soldering.

PRODUCT FEATURES

Adjustable rails accept single or multiple PCBs.

Foam pad secures components for assembly.

Choose form standard, conductive or solder-safe foam pad.

Insert, cut and solder at one station.

Hinged cover is removable for easier component insertion.

SPECIFICATIONS

For PCBs up to 19” x 9”

360H Standard Foam Pad

360HR Solder-Safe Foam Pad

360HC Conductive Foam Pad

For PCBs up to 24” x 16”

380H Standard Foam Pad

380HR Solder-Safe Foam Pad

380HC Conductive Foam Pad